Generally pharmaceutical powders consist of different sizes which make it difficult to process and make final dosage & for this milling equipments are used to reduce particle size uniformly making it easier for further mixing of solids. The smaller the particle size easier it is for drug absorption.

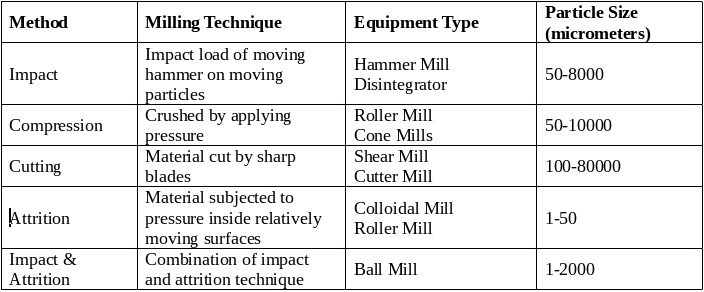

The milling equipment operates through three basic parts; first is Hopper, in which material is fed, the size reduction happens in Milling chamber after material is passed through screen & finally collected inside Discharge receiver after size reduction. There are three ways in which milling is carried out; in first size reduction is done by application of continuous pressure for coarse crushing. In second method size is reduced by blow or impact usually used for brittle materials. The third way is used for fine size reduction by using shearing forces through grinding or abrasion. So broadly milling is done through impact, grinding & crushing or a combination of these forces. Different mechanisms & milling equipment used for size reduction is given below

The Milling can be dry or wet depending on whether product undergoes physical or chemical changes in water. Final output depends upon the feed rate, speed of the machine, screen size, properties of the material like moisture content, hardness, stickiness, melting or softening point, abrasiveness, bulk density etc. Knowing the properties of the material is important to choose the right milling equipment.

Quadro today is one of the world leaders in providing conical mills for pharmaceutical industry for obtaining optimum milling output.

To know more, visit http://www.idexindia.in/quadro/comil/ or call on 18002679955. Also you can mail us on info.fmt@idexcorp.com